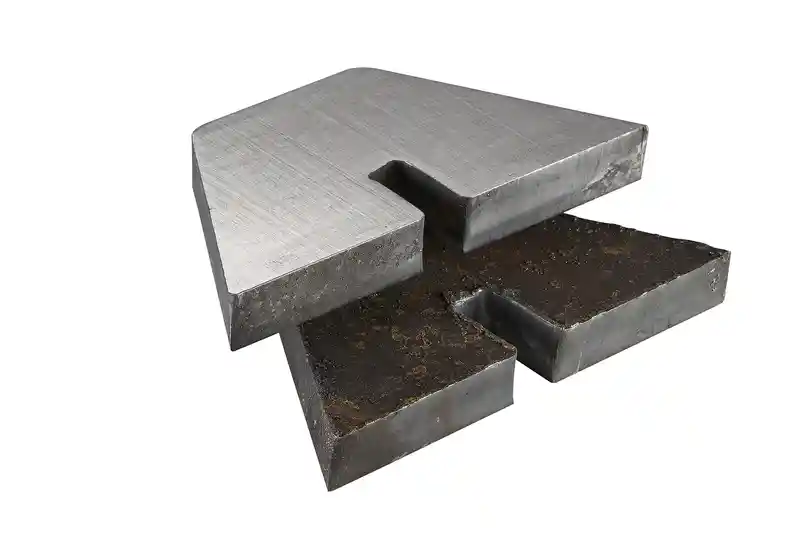

Deburring / Edge-rounding / Oxide removal / Deslagging / Hair-line

Materials:

Steel plate, stainless steel plate, aluminium plate, copper plate, titanium plate.

Applications:

Sheet metal

Punched parts

Semiconductor related parts

Architecture material

Machine structure

Ming Ping is a professional sander manufacturer built up by a group of expert engineers and management of IUD-deburring machine-dry sanding (table fixed).We focus on manufacturing and service fields, and are committed to research and development of cutting-edge technology products. To offer flawless products, we continue to strengthen in-line quality control in particular, coupled with intensive personal training.

| Model | - | Working width |

|---|---|---|

| ITD | - | 300 |

| ITD | - | 610 |

| ITD | - | 915 |

| ITD | - | 1300 |

| Model | - | Wokring width |

|---|---|---|

| IUD | - | 300 |

| IUD | - | 610 |

| IUD | - | 915 |

| IUD | - | 1300 |

Standard

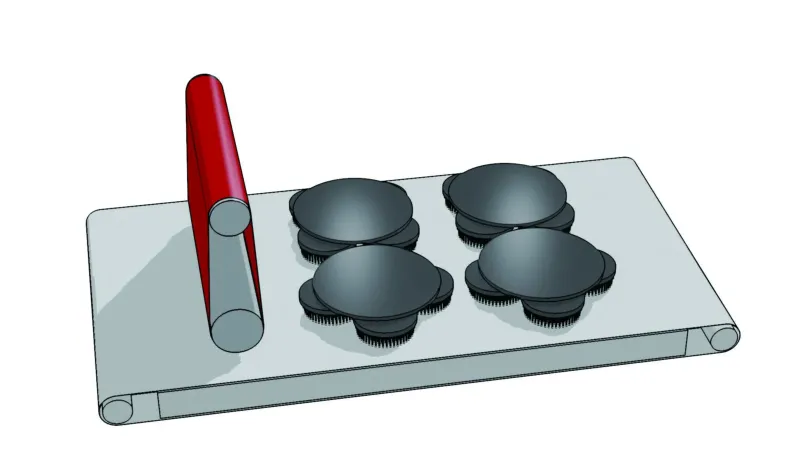

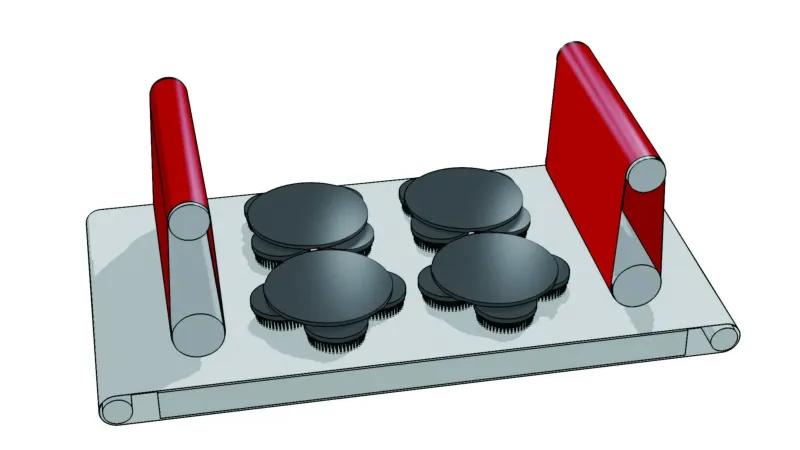

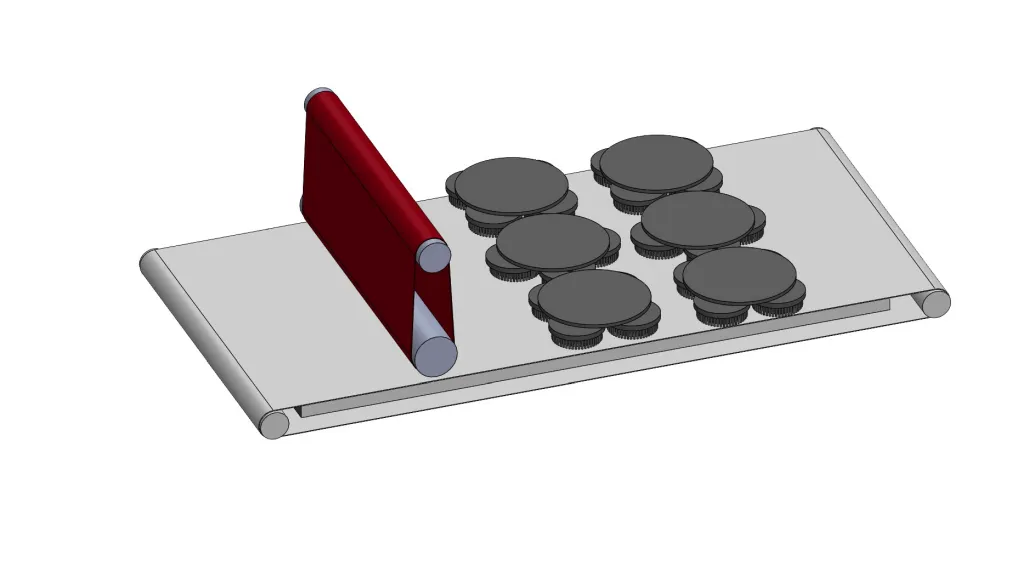

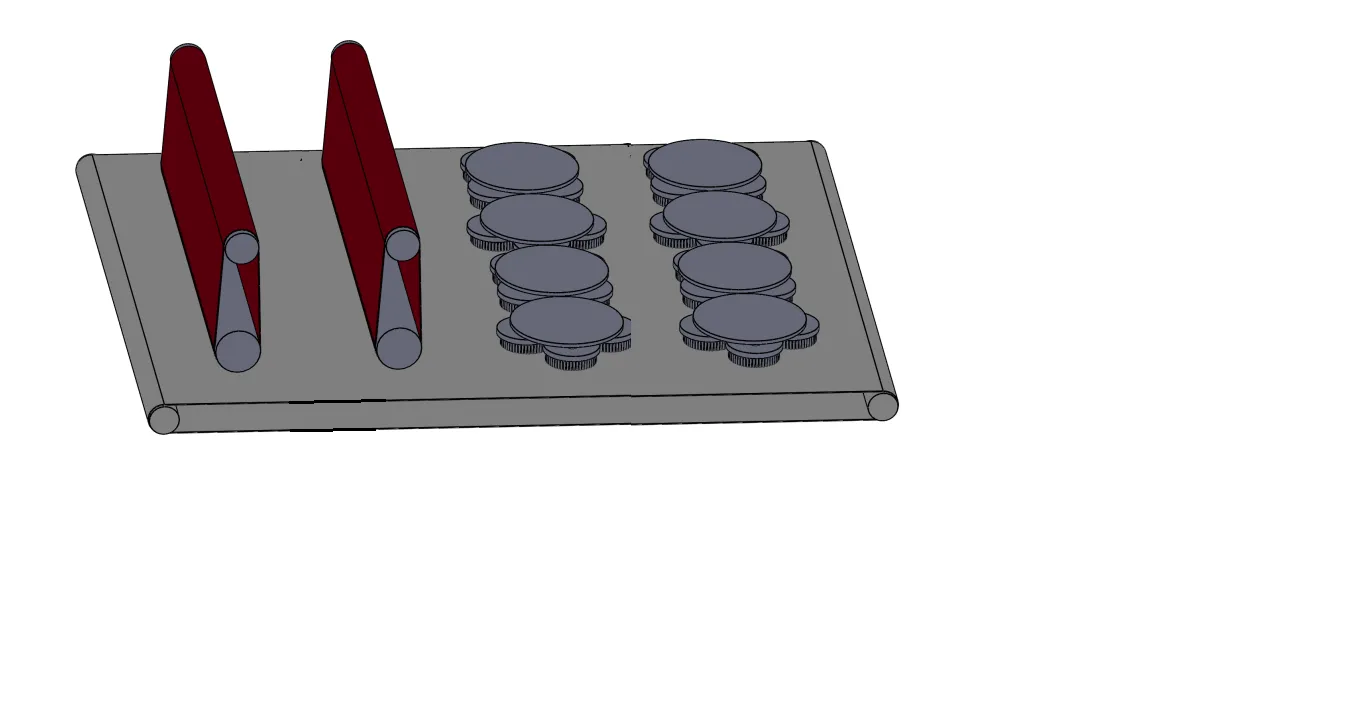

1.Patented planetary disc brush structure. Rotates both main disc and inner brushes and swing at the same time to achieve efficient deburring.

Advantages:

I. Easy-maintenance. Use common tool to dismantle and change a new disc.

II. Multi-function. Change different disc brush to accomplish different surface.

III. High-efficiency. Patented disc brush structure spinning with high speed to enhance the deburring result.

2. HMI touch screen operated. Breakdown alert by alarm bell, flash light and photo on the screen.

3. Electric eye for sanding belt tracking.

4. Alarm bell and flash light.

5. Speed change for feeding, controlled by Inverter (VFD). *Feed speed: 3-15M/min.

6. Speed change for sanding and disc brush, controlled by Inverter (VFD).

7. Air jet cleaner for sanding belt.

8. Rubber Endless Belt - oil resistant.

9. Automatic device for feed belt tracking.

10. Automatic to stop a machine when sanding belt off.

11. Pressure shoes: by rubber roller.

12. Outfeed drawer for easy clean-up.

Option

(1) S head: non-woven roller.

(2) Dust collector.

Download

Download